MICROFACTORY

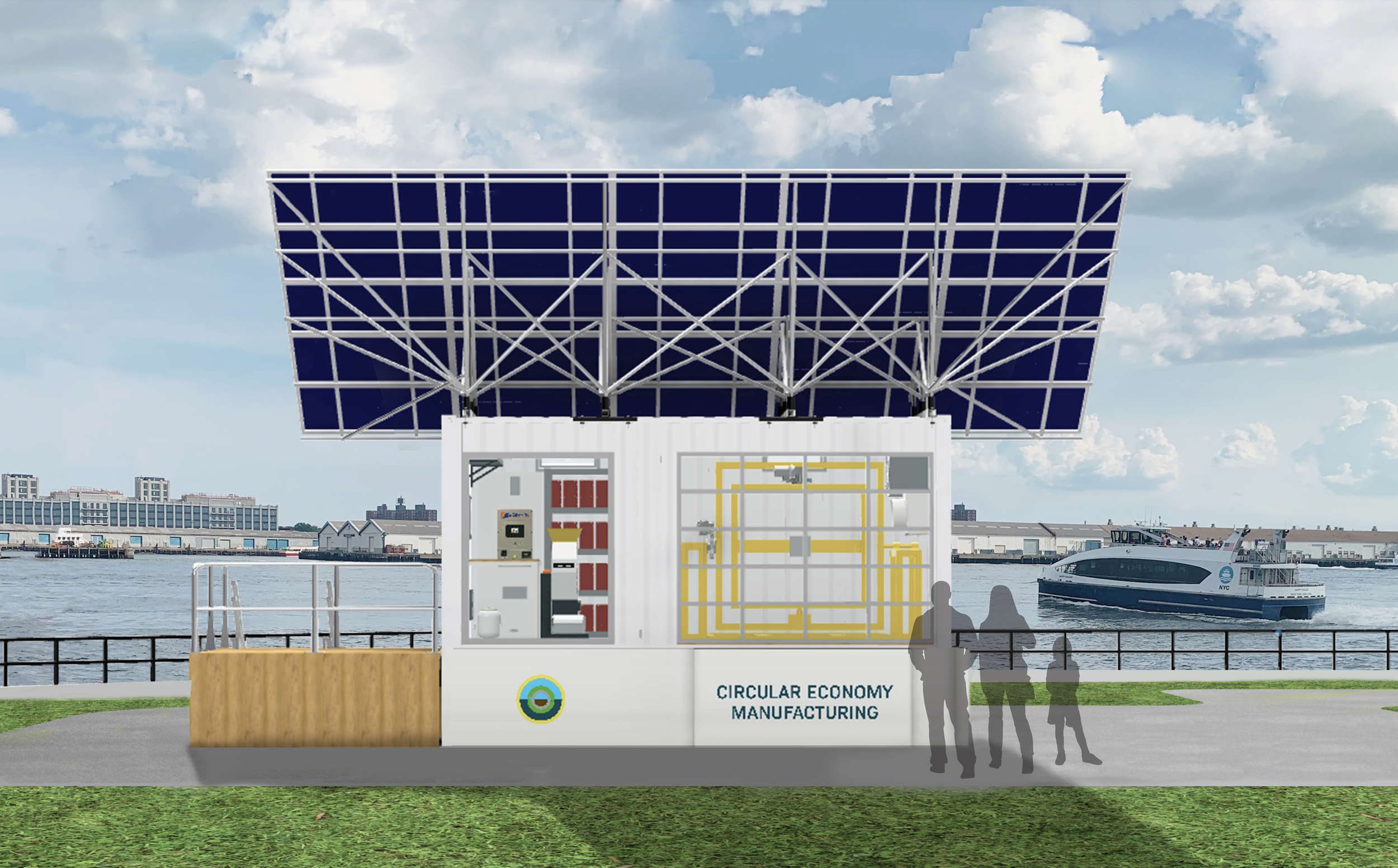

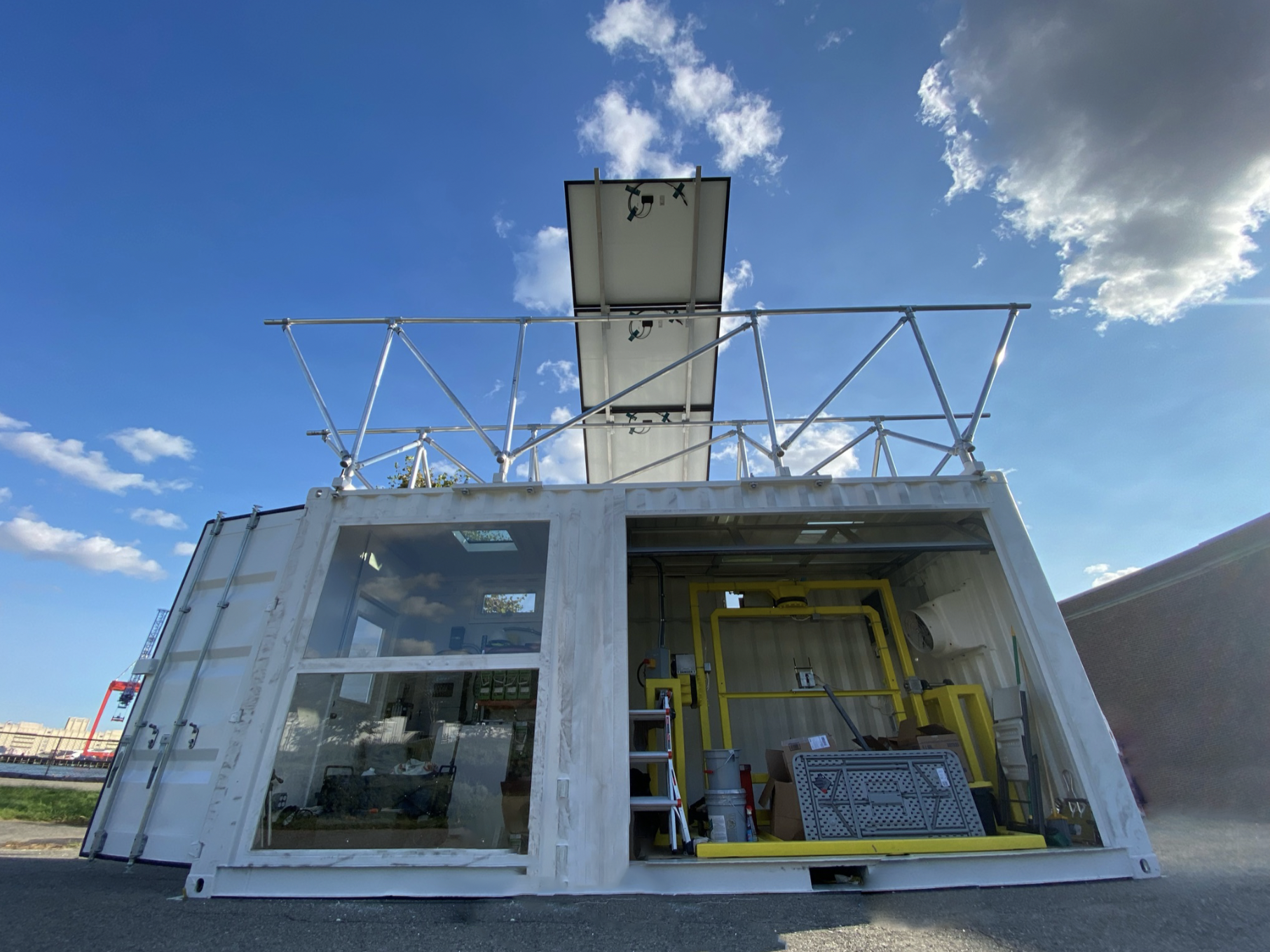

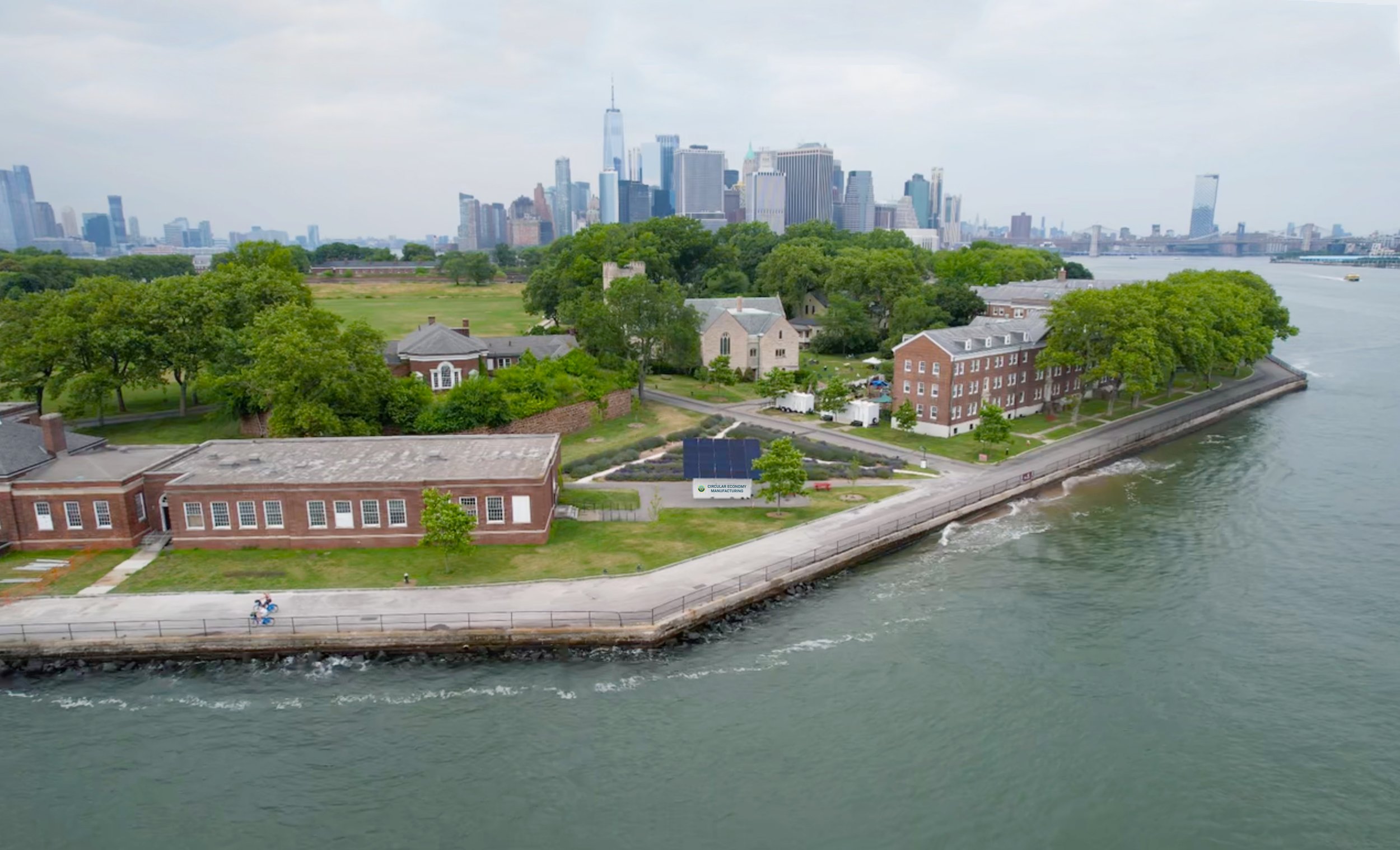

Circular Economy Manufacturing (CEMfg) operates a proprietary solar-powered MicroFactory shipping container on Governors Island, NYC. Our off-grid operation rotationally molds consumer and urban infrastructure products from recycled single use plastic (such as laundry bottles) using a pioneering energy-efficient mold heating technology. Manufacturing within our MicroFactory operation helps to reduce the dependency on fossil fuels, advance zero-waste initiatives, provide local jobs, and create well designed products from our abundant plastic waste.

EVOLUTION

While designing the MicroFactory, we worked through various iterations to fit all of our necessary equipment within the constraints of a 20ft x 7.5ft shipping container. Every inch of the space is utilized effectively and all equipment is positioned for ease of operation and public viewing. Now that we have our first MicroFactory operational, we are excited about all the MicroFactory possibilities in the future!

ROTATIONAL MOLD ASSEMBLY

Our Rotational Molding Machine (Rotomolder), is smaller and more energy-efficient than its fossil fuel powered counterparts. Additionally, our product molds contain efficient electric heating elements that heat the mold quickly and effectively, saving energy during the manufacturing process.

Traditional “Oven Rotomolding” is powered by massive fossil fuel-powered ovens that waste energy heating the ambient air rather than just the mold. This is neither environmentally sustainable nor, with energy costs on the rise, economically sustainable.

Multiple product molds can be clamped to our Rotational Molding Machine, resulting in more products per cycle. For example, we can fit six large street traffic cone molds within the 4.5 ft square inner rotating frame.

Gi Globe Mold clamped in Rotational Molding Machine

Six large traffic cone molds fit in our Rotational Molding Machine

CONTAINER BUILD

Shipping containers are extremely durable structures built to carry heavy cargo and endure rough and unpredictable weather conditions. The fact that they are light and easy to transport around the world makes them great for office spaces, tiny homes, and in our case MicroFactories!

Our repurposed shipping container features a large viewing window, clear garage door, skylights, clerestory windows, cooling fans, and entrance doors. It is painted white to reflect light and absorb less heat, keeping our space and equipment cool in the direct sunlight.

GOVERNORS ISLAND INSTALL

Over several weeks the Circular Economy Manufacturing Team worked to install the solar system on Governors Island. Taking it one row at a time, we hoisted up 25 solar panels atop our custom built solar structure. After everything was secured and wired together, off-grid solar-powered manufacturing commenced.

Container delivered to our site next to Governors Island Lavender Field

Rendering we made to help us understand the steps to install the solar array

Timelapse of solar row 2 being installed

COMPLETE

We now have our 10 kW solar system fully installed onto our MicroFactory!

When sunlight hits our solar panel array, photons (particles of energy) are converted into electrons. As electrons pass through the cells of the solar panels, they’re converted into direct current (DC) electricity. That electricity is sent to an inverter inside the MicroFactory which converts it into alternating current (AC) power. The AC power runs to our shredder, rotomolder, lights, and outlets so we can make products from recycled plastic. All excess energy collected by our solar panels is stored in our battery bank.

Want to see the process for yourself? Come Visit Us on Governors Island!

OUR FUTURE

Eventually, our goal is to have several solar-powered MicroFactories in cities around the country, and eventually the world. This includes an expanded, two-container MicroFactory with more solar and two rotational molding machines, as shown below. We hope to implement many of these MicroFactories in communities that have unjustly received the consequences of a single-use society. We believe the future of manufacturing and product design empowers people, prioritizes environmental health, and localizes supply chains while still being financially advantageous.

EXPLORE OUR MICROFACTORY IN 3D

Open up the model up in full screen, navigate it, explode the model to reveal its different components, and more.